Hexagon Wrap Around Deck Stairs

by Scott

(NJ)

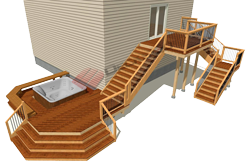

I am installing new deck over an existing frame. the shape of the deck is a hexagon.

The client wants steps of of three sides of the deck. What should the layout of the stringers on the corners be?

Comments for Hexagon Wrap Around Deck Stairs

|

||

|

||

|

||