The deck foot anchor™ can help anyone Save Time, Money and Labor

No heavy equipment. no sledge or jack hammers. no digging. no mixing cement.

Thanks to the Titan Building Products' Deck Foot Anchor™ anyone can effortlessly install ground anchored deck footings at a fraction of the cost of concrete footings.

If your deck can be Free Standing - not attached to the ledger of your house - and 80% or more of all residential decks can be - you are going to love this product.

Just use an electric impact wrench and easily drive the anchor down - or reverse if necessary.

It is a far more secure system, for floating decks as low as 2" to as high as 6' or 7' (with proper bracing) above the ground, walkways, sheds or other lightweight structures, than concrete blocks.

Keep reading... or click the link below to BUY NOW.

Secure. Fast. And Easy.

It's the first helical ground anchor footing system that installs easily with a lightweight hand held tool.

Your deck remains firmly anchored to the ground and won't be blown away in the next high wind storm.

watch the video

Just drive the anchor down using an electric impact wrench. It does all the work.

This

site is on clay with a 3" bed of 3/4" or smaller crushed gravel. It

compacts nicely over the clay and also allows rain water to pass through

without eroding soil.

Just click the link below to BUY NOW.

How the deck foot Anchor works

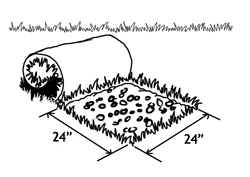

Prepare and level the area, about 24" (60 cm) square by removing any sod and laying down a few inches of ½" and smaller crushed stone (not clean). Stone dust is ideal.

This compacts nicely and is porous so that water can drain freely without eroding soil.

WARNING: If your soil is full of rocks or roots, you likely will not be able to use this kind of system or any spike system for that matter.

Fit a 12mm six point socket over the hex headed end. (A ½" will work, but it is not recommended because it's a bit loser and you might strip the hex drive head.)

Drive the anchor down until the welded stop washer on the auger shaft is almost in contact with the soil. Stop and put the load plate over the drive head. Set it on the stop washer. Put the lock washer on top of the plate and turn the nut onto the threaded rod until the hex drive head is full exposed.

Drive the anchor down again until the cap plate contacts the ground and the underside of the upper nut. Once you feel tension in the auger, stop driving it.

Fit a 24mm or 1" six point socket and turn the nut until it fully compresses the load plate against the stop washer underneath the plate.

Stop turning the nut as soon as you feel the plate has contacted the stop washer. This compresses the plate on the surface below.

Warning: Make sure the plate is perpendicular to the the auger so it will seat firmly on the stop washer.

Put the post saddle over the drive rod and adjust it laterally. Put the second washer over the drive rod and turn the second nut on to the rod. Fit a 24mm socket over the nut and tighten it until the saddle is locked in its final position.

Get the Deck Foot Anchor installation guide.

Keep reading... or click the link to BUY NOW.

"free standing Deck": What Does That Mean?

Let's take a closer look at what a freestanding deck is in order to understand how the Deck Foot Anchor can be used to support it.

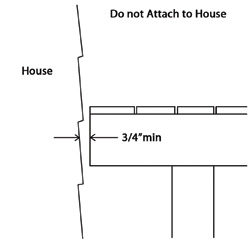

A "Free Standing" deck, also called a "floating" deck, is not supported by a dwelling. The deck is not attached to a ledger board which is in turn bolted through to the rim joist of the floor deck of the dwelling.

As stated above, a deck that is not supported by a dwelling need not have footings that extend below the frost line (IRC Section R.403.1.4.1, Exception 3). This saves builders and DIYers the major expense and skill of ripping apart the envelope of the house in order to secure to the ledger and install the proper flashing to keep the connection dry.

Allow 3/4" to 1" of clearance between the siding of the house and the deck for any seasonal movement that may occur.

A floating deck will simply rise up and down over the course of the winter.

avoid ledger work: it's complicated and expensive

You Have No Idea What You Are In For

Unless you are an experienced carpenter, do not try to attach your deck to a ledger on an existing home.

Properly attaching a ledger board to an existing home can be a major task. If the ledger is built during the construction of the house then all the details like flashing and siding are so much simpler.

This Is A Simple Example

This ledger was installed after the house was built. The exterior was vinyl siding so much easier to deal with then brick, stucco or cementitious fiber board. But this was still a big job.

The rim and floor joists were engineered I-beams so the very first difficult task is to determine exactly where the rim joist is and remove the siding to match it.

Then each space between the joists had to be block with 2x8 material because the rim joist was OSB board.

Double Overlapping Flashing Is Essential

The first layer of flashing extends from under the ledger to at least 4" above the cut line of the siding. The second layer slides over this layer and will hang over the ledger board with a drip edge to direct water down.

Go up high enough under the existing siding to ensure things stay dry. If you are dealing with a masonry facade you have a ton more work to do and that is a lesson all unto itself.

Carefully Avoid Other Obstacles

Complicating this job was a natural gas line that the gas grill was going to connect to. This ledger had to be accurately cut to fit perfectly.

Building a free standing deck with the Titan Deck Foot Anchor avoids all of these issues. And thankfully the vast majority of residential decks can be freestanding.

Just click the link to BUY NOW.

frost: what happens with a free standing deck?

A deck that does not have frost footings will float on the surface of the grade if the soil freezes and expands in the winter time.

Wet clay will expand the most and sandy soil the least. It will then settle back down again in the spring when the soil thaws.

This movement is virtually imperceptible unless you measure it against the side of your house.

The amount of annual up and down movement depends on the amount of water in the soil and the depth of the frost line.

An exceptionally cold winter with wet clay and four feet of frost could easily expand the soil by ¼" to ½".

But on the Titan Deck Foot Anchor, your deck will safely weather the ride.

irc does not always require footings below frost

did you know the irc does not require footings below frost depth for freestanding decks?

This is something many DIYers, builders and even building inspectors are not aware of. But it is true.

The rationale is that if a light-framed structure is not attached to a building, it does not have to be supported by frost footings. This permits freestanding decks, walkways, ramps, shed platforms and other similar structures to be supported without frost footings.

This in turn saves thousands of dollars in labor for precise flashing and detailed ledger work for the homeowner, and the builder. It means a builder can price a job lower than one requiring a ledger connection.

Not every deck can be freestanding such as walkout decks from second stories which should always be ledger connected and therefore supported by frost footings.

However, any deck that is 6' or less above grade is a potential candidate for a freestanding structure. Local counties and municipalities may have varying height restrictions on freestanding decks but 6' and lower seems to be typical.

R403.1.4.1 Frost Protection. Except where otherwise protected from frost, foundation walls, piers and other permanent supports of building and structures shall be protected from frost by one or more of the following methods:

1. Extended below the frost lilne specified in Table R301.2(1);

2. Constructing in accordance with Section R403.3;

3. Constructing in accordance with ASCE 32; or

4. Erected on solid rock

Exceptions:

1. Protection of freestanding accessory structures with an area of 600 square feet (56m2) or less, of light-framed construction, with an eave height of 10 feet (3048mm) or less shall not be required.

2. Protection of freestanding accessory structures with an area of 400 square feet (37m2) or less, of other than light-framed construction, with an eave height of 10 feet (3048mm) or less shall not be required.

3. Decks not supported by a dwelling need not be provided with footings that extend below the frost line.

Terra-Shift™: deck Shock Absorber system

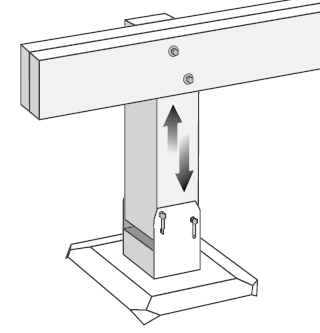

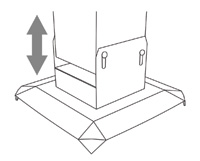

Our patented "Terra-Shift™" technology was developed specifically for the Deck Foot Anchor™. It protects your support post to beam connections in the event of seasonal soil movements.

It allows any support post under a beam to slide up and down independently in the bracket whenever there are uneven forces or stress.

So all your critical connections remain protected in the event of frost. It's like a shock absorber system for your deck footings and posts!

Friction Release Bracket

The Terra-Shift™ post bracket allows a post to slide up in the bracket under at least 50% less force when compared to a standard vertical slot.

When nature decides to exert force on your deck, the footings, posts and beams work as complete system.

Posts can temporarily rise up in the bracket so that the post to beam connection is not pulled apart.

securely anchored: ready for high winds

Decks supported by concrete blocks that rest on the surface are susceptible to uplift in high winds and have to be secured to the ground with a webbing of cables and ground spikes. The Deck Foot Anchor™ holds your footings securely to the ground.

Almost 2/3 of the United States and parts of Canada are in high wind zones.

Just click the link to BUY NOW.

Engineering Testing for COMPRESSION Strength

Compression load testing was done to determine how much weight the footing anchor device itself can support. The results were impressing. Three samples of the Deck Foot Anchor were crushed in a hydraulic press until destruction of the post saddle was achieved. The minimum load from the three sample test was 19,000 lbs!

Clearly, no soil can support 19,000 psf so the limiting factor you have to consider is the bearing capacity or your soil. Just contact us and request a copy of the report if you need this.

PULL OUT RESISTANCE

Pull out resistance from undisturbed soil varies on soil type.

If you are building a project where known uplift data is required this product may not be suitable for your application. We do not have uplift data for different soil types at this time.

However we are engaged in comprehensive uplift testing program which will be completed in 2021 and will publish that data as soon as it is available.

Lower Your Materials Bill by 30% or more

Check your materials estimate and you will find that the cost of traditional footings is easily 25% of your total bill and more likely 30% or more. Yes, more! And this does not even include the time taken to mix all that cement.

If your deck can be built as a free standing structure you can avoid all of this extra expense and effort.

how the deck foot Anchor™ pays for itself

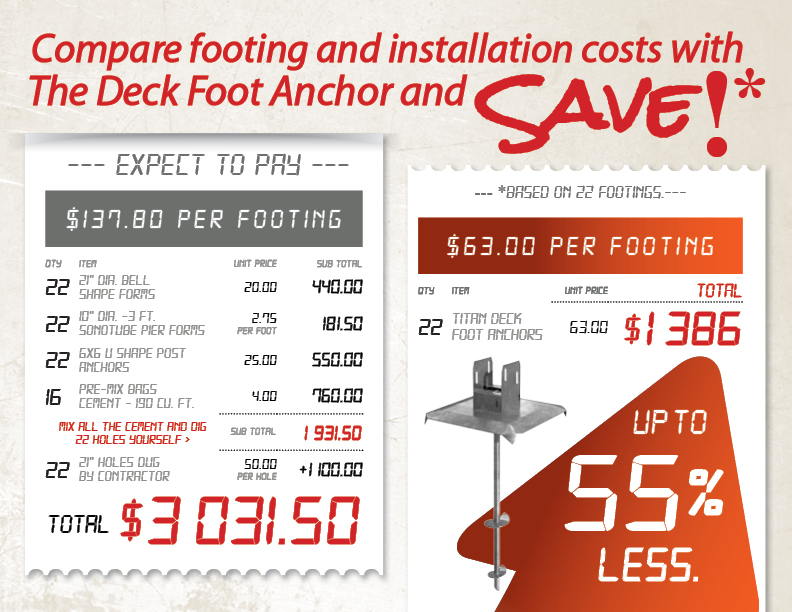

Here's a quick cost comparison. The deck above used 24 footings. If you use a concrete system with 21" diameter bell shaped form sand sonotube piers with pre-mixed concrete bags you could get by with only four footings on the upper deck rather than the six I used.

But the lower decks remain unchanged. So we will do this based on 22 footings.

The Deck Foot Anchor™ costs about $60 per footing. Your bill would come in around only $1386. About 30% less!

But it's up 55% savings if you use add the cost of digging the holes. And this does not include the $1000 or more you will save by not having to rip apart your siding and flashing a new ledger connection. When you consider that the savings are truly huge. And you avoid the risk of an improperly flashed ledger.

The real savings is time and effort. As you can see it's a simple installation process. Why use concrete unless the specific demands of the job called for it? Just click the link to BUY NOW.

Ground level or higher

Ground Level

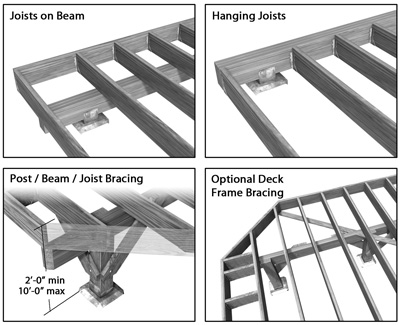

You can build your deck with joists as low as 2"-3" above grade if you wish.

Simply hang the joists from the perimeter joist. If you want to extend the deck beyond the footing, extend the side perimeter joists 6"-10" and fill with blocking joists along the length.

Easily Up To six Feet

With proper bracing in both directions from 6x6 posts to beams, you can make a six foot high free standing deck as solid as a rock. It's possible to go even higher but it is not intended to support decks at a second floor elevation.

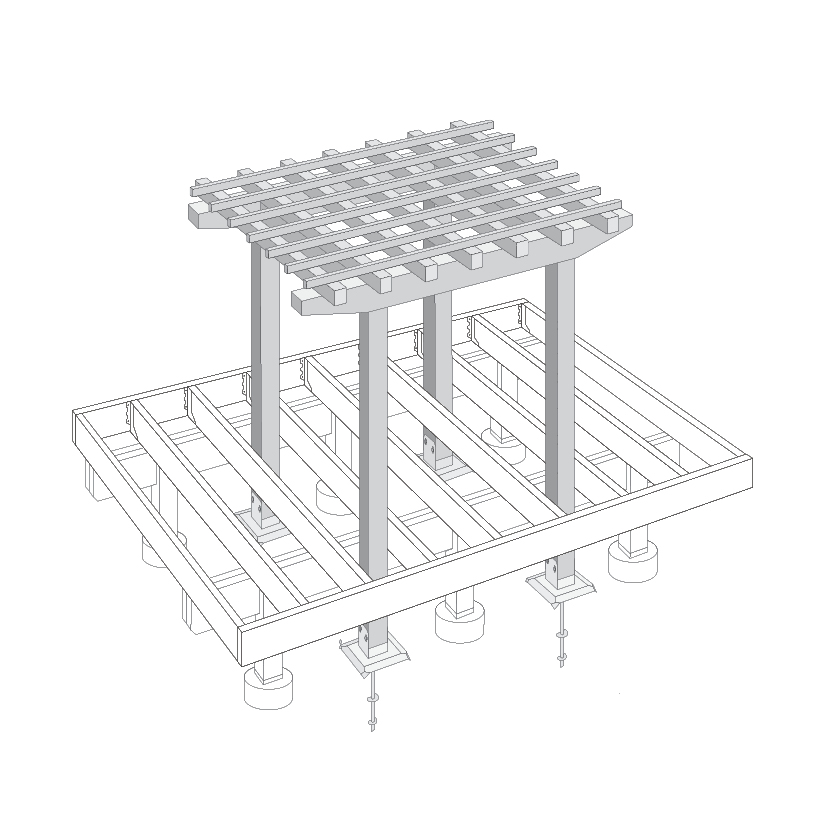

pergolas using deck foot anchor

You can even build ground anchored pergolas using the Deck Foot Anchor so long as the pergola is built to include any necessary bracing to keep it stiff and rigid.

The Deck Foot Anchor can easily support the weight but it does not provide lateral resistance for an eight foot tall structure. Be sure to brace posts to beams as necessary to make the structure rigid.

In this case, the deck was framed around the pergola. But the pergola could also stand on its own.

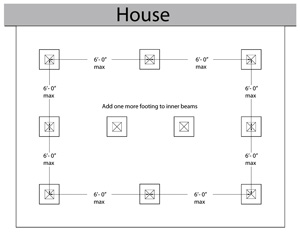

How Many Footings do you need?

The Rule of Thumb is 6'-0" apart for each footing. This corresponds to a design load of 50 psf and tributary areas over each footing of 36 sqft.

So the total load imposed on the soil below each footing would be a maximum of 1800 psf as the footing is just slightly larger than 1 sqft.

Not sure how many footings you will need? No worries, try this Footings Calculator. You input the dimensions of your deck and the estimated soil bearing capacity and it will show you the number of footings so you do not exceed the soil's load capacity.

Just click the link to BUY NOW.

The Deck Foot Anchor™ Exposed

The Deck Foot Anchor™ is comprised of three parts: a Post Bracket, a Load or Cap Plate, and an Auger.

Auger lengths are 24" or 36". Use a 24" for most applications where soil is hardest. Use a 36" where soil is softer, sandier or you just want maximum pull out resistance.

Longer auger length does not make the footing more resistant to frost nor does it make the footing immobile against frost. The Cap Plate will always rest on the surface and the entire deck will rise up and down 1/2" or so during a winter if the soil freezes.

here is a real deck job

This was a large multi-level deck that really shows off the usefulness of the Deck Foot Anchor™. Three separate areas. All intricately designed to wrap around a hot tub spa and create intimate areas.

The first area was off the back patio door about 3-1/2' high. The others were lower level platforms over a gradual grade sloping away from the house.

All 24 footings were installed before lunch hour.

Can you imagine the work involved if we had to dig and cement for this job?

Another building benefit is being able to use the Deck Foot Anchor™ to easily drop beams within 2" of the grade. Try doing this with a block...

Low set beams

You can also hang joists from beam face to beam face if your really wanted to hide all the beams of a low level deck. That is next to impossible to do with blocks.

First, if we used concrete blocks we would have had trouble figuring out how to get the deck joist framing as low to the ground because they sit higher.

Second, the deck would just loosely sit on them. Here, each footing and post to beam connection is secured to the ground.

Third, we didn't want to see cement blocks when you walked by the highest level deck.

Case studies of real jobs

The Deck Foot Anchor™ is a DecksGo Recommended Product. It's one that we are confident you will be happy with. It's been tested in some of the harshest cold and sweltering heat temperatures and it has proven to be as tough as nails.

DecksGo was the first company to bring this product to the market, and you can expect more great "first" moments like this.

This is what we do - try to bring you leading edge building solutions before anyone else.

Home > Deck Foot Forum > Titan Deck Foot Anchor