Tips for Rebuilding Deck Support Posts: Building Strategies and Wood Types

I'm from Massachusetts and I have a question about the type of wood to use for deck support posts.

I have a 12'x16' deck that is 11' off the ground. It is attached to the ledger along the house and supported by three support posts. The 4x4 support posts are twisted and need replacing.

I plan to use 6x6 posts and notch 2" from the top to help secure the posts to the sistered 2x10 main beam. The main beam will sit on the 6x6 and 2" of the post will go inside the 2x10's and be lag bolted.

Since it is a nice deck, I would prefer to use non-pressure treated wood so I can paint it white. I would seal the ends, then prime and paint the wood so hopefully it would not rot too fast.

Can I use cedar or is pressure treated (PT) lumber a better idea?

If PT is required, where can you get decent quality PT wood (not big box stores like Lowes or Home Depot). Are there grades of PT, center cuts etc. that would be best? Editor’s Comments

A 6x6 post is by far the best dimension to use for support columns. It is rock solid, less likely to twist, and in my opinion, always the best choice.

Notching the Structural Posts to the Joists

As you mentioned, it is in fact best to notch your 6x6 support post on one side to allow a shoulder for the 2x10 to rest on it and to be securely connected laterally by using ½” carriage bolts.

You describe your idea of notching the post a bit differently than conventionally done. It seems like there are two ways you may interpret your question regarding the exact detail of the 6x6 beam notch and the 2x10 joists.

The first, mentioned above, requires notching one side of the post to allow a shoulder for the beam. The second insinuates notching both sides of the post and setting the beam on either side of the post. Each post notching approach is described in the following section.

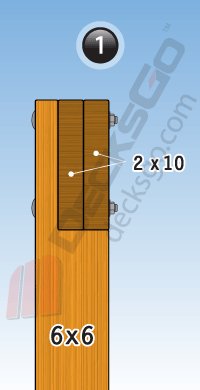

Notching Approach #1

The best approach is to notch the 6x6 post on one side of the 2x10 joist. This approach is illustrated in the following image.

Here you can see the 2x10 laminated beam (or sistered as you refer to it) securely connected the post. A benefit of this option is that the final structure is very stable.

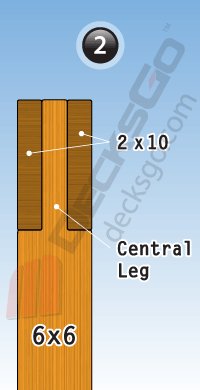

Notching Approach #2

You mentioned having a vertical portion of the post “inside” the 2x10 which tends to suggest that you want to notch both the left and the right side of the post. This approach would leave a 2” central leg on the top of the post, which is not ideal for stability purposes.

Here you can see that each of the 2x10’s would be fitted and rested on the two notches that you have created on the post on either side of the central leg. Securing the joists on either side of the post in turn would leave a space between the two joists, a marginally less stable configuration. To stabilize each 2x10 you would have to toenail through each joist into each 2x10 beam. As the beams dry out it is possible that they can warp or twist a bit depending on the species and the quality of the grade.

I would not recommend notching your posts in this way.

When you “sister” the 2x10’s you make them into one unitary beam. Its more stable and a much better way to build.

Cedar vs. Pressure Treated: What type of wood is best for the structural post?

All building materials have both pros and cons. When embarking on a building project, it is important to consider what works best for you. You may want to consider: what species are readily available, the cost of the different types, and the longevity. Do you want to redo this project in a few years? Or would you rather not?To help you out, I will briefly describe a few pros and cons for both cedar and pressure treated lumber.

Pros and Cons of Cedar

Cedar is a popular choice for outdoor construction. Other softwood construction grade species like western cedar, hemlock-fir, and douglas fir are also sufficient.Cedar is more than strong enough to function as a support post and very durable. Generally speaking, cedar is naturally rot, decay, and insect resistant. It is also resistant to warping, twisting, and cracking when exposed to moisture.

The biggest draw back of cedar is the cost. If you are building on a strict budget, using cedar may not be feasible.

Pros and Cons of Pressure Treated (PT) Lumber

PT is the most commonly available construction lumber for outdoor structures. It is usually pine but can also be hem-fir and even spruce in some cases.PT is strong and extremely durable. It tends to have a very long life-span. Considering these factors, you will mostly likely not have to replace the structural post for a very long time. Lastly, PT is the cheapest option.

Pressure-treated southern yellow pine is most prone to warping and cracking because its grows so quickly and the growth rings can be as large as 1/4" per year. That means they retain more water and when the water evaporates the wood is more prone to movement.

Sealing the Bottom Ends of the Support Post

With both types of wood it is important to seal any exposed ends. This means that if you cut your PT to size the exposed end of the post should be sealed.In case you were wondering, your support columns should always be elevated above any concrete surface they are connected to, to prevent possible rot and water damage. If the elevation is less than 1" above concrete you MUST preserve the ends according to the IRC. You can avoid treating the ends of the structural post if the stand off base is 1" or more above the concrete. But why not take the time to treat the ends anyway to be safe.

Painting the Posts

When it comes to painting pressure treated lumber I would advise you to talk to someone in the paint department who is knowledgeable about outdoor paint and how it reacts with different chemicals and materials. Generally, a solid stain is a better way to go for outdoor lumber. This will give you the visual effect of using paint. However, if you are looking for white, you may have to specifically ask for a tint.Where to find better quality lumber

The box stores like Home Depot and Lowes go to market with the message of selling at a low price. This means for some commodities like dimensional lumber, a sacrifice often occurs.To get the lowest price on lumber you have to buy lower grades, some times lots of lumber that would otherwise be culled. So, there is a reason they offer lumber so cheap and you get what you pay for.

The independent lumberyards tend to have a reputation for better quality and often source their lumber from better mills. This is one of the lumberyards differentiation points from box stores.

So, if you are in the market for better quality PT, I would suggest looking up local lumberyards in your neighborhood.

Did you find this article helpful? We'd love to hear about it! Share on your preferred social media platform on the left.

Comments for Tips for Rebuilding Deck Support Posts: Building Strategies and Wood Types

|

||

|

||