Western Red Cedar 5/4 x 6 Deck Board Fastening & Finishing

by Van G

(Toronto)

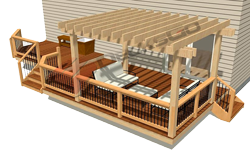

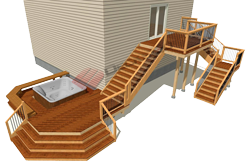

I've got my two decks all framed up and I'm ready to lay down the boards. When I started out we had planned to use Ipe, but then we added a second deck, post and beam features...... You get the idea.

Job Specs: Location = Toronto, Boards = 5/4x6 Western Red Cedar #2 or Better Knotty, Two Decks = 640 sqft, Finish = UV Seal

I hope to get some consensus on best practices for the following:

Fastening: How should I fasten the boards? Top or Hidden

Which hidden fastener system works well with WRC?

If face screwing, which screws should I use and do I need to pre-drill?

Protecting:

I would like to preserve the warmth and natural tone of the finished deck. I plan to use a UV sealant like Cabot. I realize this will involve washing the deck semi-annually and hopefully seal every other (or more).

If this was your deck and you had plenty of hands to help, would you pre-finish boards: sand, seal, cut & end seal?

What is best practice?

Board Pattern:

I picked up a FHB deck magazine a couple weeks back which showed a nice board detail on an Ipe deck. Can't remember the specific pattern name, but it was a picture frame border, 3 courses wide, butt joints which used a biscuit joint for strength.

Can I still attempt this pattern with WRC, or is it too soft?

Comments for Western Red Cedar 5/4 x 6 Deck Board Fastening & Finishing

|

||

|

||