What Are Flat Concrete Forms?

Flat Concrete Forms - Cool Idea Indeed

When your building project calls for concrete footings that must be frost heave resistant, there is no way around having to dig and mix concrete. Other than using expensive engineered helical piers.

But here is a great solution that mitigates a couple of the major headaches associated with traditional foundation piers.

You Still Must Dig and Mix

This hexagon cardboard form, called the Flat Form comes totally flat. About 1/2" thick and has a built in bell shape when filled.

Maximum height is 48" but probably a bit less the more you flatten out the bell shape. But that's good enough for frost levels in most places.

source: deckmagazine.com

Save Tons of Space and Transporting Hassles

Have you ever tried to pick up and handle two or three 10' sonotube forms at a time? It's not pleasant. When you're not dropping them you're juggling them all over.

What about transporting them? In a word...HASSLE! They roll all over the place and you have to carefully strap them onto your roof rack with the help of a friend.

If you have a pickup truck you can of course toss them in the bed but they take up so much room you are left with no room for your other tools and supplies. This is not the same scenario with flat concrete forms.

Congratulations to the mind behind inventing the Flat Form...that person was really thinking.

And there are more benefits...

Save Money on Cardboard Bell Shaped Footing Forms

Yes, those plastic bell shaped footing forms are great and serve a purpose. But if your project is small enough, and most are, why spend another $25 on a plastic form unless you have to?

Other Innovative Aspects to this Form

The bottom has vertical scores in the cardboard creating a

series of independently moving tabs that can be pushed out in your hole

to the desired circumference. This creates the "bell" shape.t

There is an option to insert the center support disk inside the tube just above the bell perforations. The center disk can provide extra rigidity to the form while you are backfilling around the bell shaped base.

Slip the cover over top of form and slide assembly into the hole (bell cuts down). Fill bell to desired depth and back fill to above bell cuts. Secure forming collar with landscape spike and fill with concrete.

After concrete is cured, cut above forming collar and strip away from concrete pier.

Take No Space in Truck

You will be way more efficient and organized with both your time and money when you can carry 20, 30 or 40 of these inside the bed of your truck.

Imagine just trying to transport three or four traditional concrete forms and bell footings?

Another good reason I thought sharing this solution with you was worthwhile.

Where Can You Find Them?

New to Market

The best way to buy this product is to contact Flat-Forms directly.

Remember, every time you buy from them you are supporting a brand-new company and gradually they will grow their distribution channel through local building supply stores and wholesale distribution.

So, now you have the benefits of flat

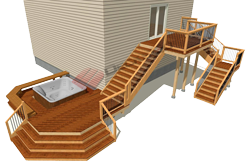

concrete forms. Perhaps you will find this helpful the next time you're building a deck.

Home > Building A Deck > Flat Concrete Forms