BUILDING A DECK Railing WITH the TITAN POST ANCHOr™

HOW A DIY'er, With LiMITED Building Experience, Rebuilt his rotting Deck & Saved a Ton of Money

After several years of Jim's wife asking him to replace the deck, he finally got around to securing a few estimates. The estimates ranged from $6k to $11k.

The $6k quote seemed low to Jim since he wanted the decking to be composite and the $11K quote seemed too high especially since it assumed the contractors would be able to reuse most of the framing.

So, in the end, Jim decided to save money by removing all the decking himself and then decide on who to hire from there.

about the builder

Jim is a Global Program Manager in the IT department for a Fortune 200 company.

He sits at a desk and jumps on conference calls all day.

His building experience consists of two sheds and this deck.

And most importantly, he drives a Dodge Stratus. Just kidding! We don't know what Jim drives.:-)

Here is what was lurking under the decking

Well, much to Jim's dismay the deck was a total loss. Some of the joists and most of the decking had rotted out. In fact, it was so rotten that he was able to pull posts out by hand, concrete and all - Jim the Superhero!!

After the demolition Jim threw caution to the wind and decided that since the deck was a simple structure, he would rebuild it himself.

What Could Possibly Go Wrong?

The process was going well until it came time for Jim to build the railings. Unfortunately, he did not plan far enough ahead and realized he did not have any posts coming up through the decking to build his railings. He had no choice but to find a solution to top mount his railing posts.

After some Googling, Jim found the Titan Post Anchor™ kit. Each kit comes with the post anchor, four lag screws (to secure the anchor to the post) and eight deck screws (to secure the anchor to the deck). Needless to say, Jim was thrilled that he found a solution to his problem and thankful he didn't have to backtrack.

IF Jim can Do It, You Can Too!

As previously revealed, Jim's building experience was limited yet he managed to install his surface mounted railing posts using the Titan Post Anchor™ easily. The fact is the skills and tools Jim required to complete this part of his project were skills and tools that most people have.

The ability to:

- Swing a 3 lb. hammer

- Draw a straight line

- Drill a plumb hole

- Pull a trigger on a power drill

The tools required:

- Pencil

- Speed square

- 1 1/4" Hole saw

- Power drill

- 5/16" Drill bit

- 7/16" Drill bit

- 3 lb. Sledgehammer

- Level

- Shims

- Clamps

The first step Jim took to install the Titan Post Anchor™ is to find the center of the post. You do this by simply drawing an “X” on the bottom of your post using a straight edge. The center of that “X” is the center of the post.

Then he set his drill to the “drill” setting and the gear selector to “2” (low torque). He had to back it out and tap the wood dust out of the bit a few times; this will depend on how soft your wood post is. He then drilled into the post with the hole saw until it bottomed out and left the plug in the post.

Builder's Tip: Anchor the post to something with some clamps before drilling. In Jim's experience trying to hold the post and drill was a real pain in the… wrist!

Jim found the next step to be the fun part. He set the end of the post, without the pilot cut, on a firm surface (he used his concrete patio). He then inserted the Titan Post Anchor™ into the pilot cut. He just eyeballed it to ensure the anchor was square with the sides of the post. Then he grabbed his sledgehammer and gently hammered the anchor into the pilot cut. When he got close to flush with the bottom of the post, he used his hammer to square the anchor with the post. Do not be shy, Jim had to bang it hard. When he was square, he finished hammering until the post anchor was flush.

Builder's Tip: You can use the pencil lines as guides and look through the holes to help square the anchor with the post. Jim used the Trex post sleeves, so even though he did not need to be perfectly square he wanted our readers to know that given his OCD (desire for perfection) he was.

it makes a nice strong connection

Jim then used a 7/16″ drill bit and drilled out the four holes for the large lag screws. Then he swapped out that bit for the appropriate socket and drove the lag screws in. You will want to secure the post for this part too. You may have to switch from the drill/driver to a socket wrench to get the lag screws all the way in. You can also use this step to get the anchor completely flush if the hammering did not do it. That is, it, your anchor installation is complete. When Jim completed this step, he said "trust me, you’re never getting that thing out."

NOw let's talk about blocking

If you look at Jim's deck photos you will notice he did a nice double picture frame border to give it some character and hide the exposed edge of the Trex decking. He loves the look but the amount of blocking required for a picture frame deck deck is more complicated. To learn about picture framing see this article.

Once Jim determined where he would be placing his deck railing posts he then crawled under his deck and added 2x8 blocking between the joists. This is typically not a difficult task but unfortunately for Jim he had to deal with a broken nail gun before finishing this step :(

When it came time for Jim to drill the holes into his expensive Trex decking he did not just measure twice and drill once he measured … well let's just say way more than once!!!

Builder's Note: Be sure the deck screws of the outside edge of the post anchor hit the rim joist; the rest can go into the blocking. Jim suggests waiting to hammer one of the anchors into the post so you can use it as a template to position the post and mark where to drill. If you are using composite decking you must pre-drill at least an inch deep into your deck board.

Once Jim was ready to mount his posts he grabbed some shims, a level, his drill gun with the proper socket and a clamp. He then lined up his post with the holes he predrilled in the deck and used his screw gun to drive the lag screws in about ½ – ¾ of the way.

Since Jim was working alone he had to hold his level along one side of the post and plumb the post side to side. He slide shims in as appropriate to hold it. Then moved the level and plumbed it front to back. In retrospect Jim recommends clamping the level to the post so you have two hands free to work with. Or you can up your game and clamp two levels on the post and plumb it both ways at the same time.

Once the post was plumb both ways, he screwed down each corner, adjusting the plumb as he went then he screwed all the screws in. Again, since he used a Trex post sleeve, he didn't strive for perfection as the sleeves provide some wiggle room and hide most errors. Plus, most people don’t walk around with a level checking if your posts are plumb.

The Final Touches

Jim used the Trex post sleeve, a flat post sleeve cap and skirt for each post.

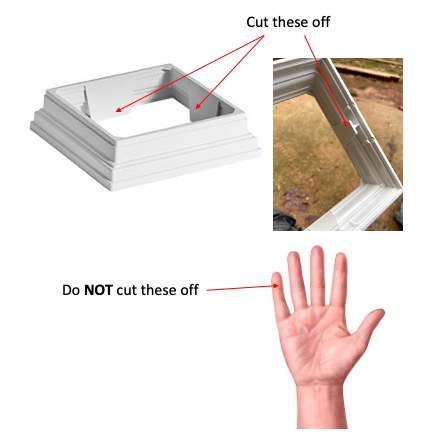

Each skirt had tabs inside that needed to be cut out. Watch out for your fingers!!

Watch the video below for more info:

Jim used an oscillating tool with a half-moon cutting blade to cut off the tabs inside his post skirts until they fit flush on his deck.

When the weather turns dryer Jim will use silicone caulking to attach the caps and skirts.

Jim was impressed with how easy the Titan Post Anchor and posts were to install and was quite pleased with how good the end-product looked.

The railing installation was another story altogether.

Next step for Jim was to finish the trim work.

the final Product - A labor of love

Happy Wife Happy LIfe :)

We are so thankful to Jim for sharing with us his experience building with the Titan Post Anchor™ along with lots of great photos. And, by the way Jim's wife is beyond thrilled with their new deck and very proud of Jim for tackling this project on his own. You can read more from Jim on his blog here.

- Home

- Titan Post Anchor Forum

- Build Deck With Titan Wood Post Anchor